Pilot project from Petting

SHT already reported on the Rendemix solution some time ago. After around ten years, it is worth taking a look at the experience gained from its use. At that time, the Schönram brewery in Petting in Upper Bavaria optimised the entire hydraulic integration of the individual stations with the Rendemix multi-port mixing valve technology, which regulates the temperature of the brew and raw beer flows with minimal energy consumption and directs them to the individual production units.

SHT already reported on the Rendemix solution some time ago. After around ten years, it is worth taking a look at the experience gained from its use. At that time, the Schönram brewery in Petting in Upper Bavaria optimised the entire hydraulic integration of the individual stations with the Rendemix multi-port mixing valve technology, which regulates the temperature of the brew and raw beer flows with minimal energy consumption and directs them to the individual production units.

The refurbishment of the internal brewery logistics was the third stage of a general refurbishment. This began many years ago with natural gas instead of heating oil, when the brewery had a natural gas pipeline laid from the off-site network to the building complex. It then converted the heating supply completely to waste heat recovery from the individual installations of the intermediate production. Finally, in 2015, it commissioned the expert company Lorenz Mayer to optimise the hydraulic circuits.

Energy requirements and costs

Hydraulic optimisation and fuel prices: What does natural gas cost? Wholesalers generally divide their offer into three tariffs: Domestic customers with an annual consumption of less than 100,000 kWh, commercial customers (commercial gas) over 100,000 kWh up to around 1.5 million kWh and industrial gas for customers with a purchase above the commercial level. These limits are not fixed and allow for deviations. The third group is not fundamentally energy-intensive industrial companies in the context of the mandatory CO2 pricing of these producers. Producers are considered energy-intensive if oil or gas purchases account for more than 15 per cent of gross value added (porcelain and glass industry, paper, chemicals, parts of the metal industry, petroleum industry). Gross value added comprises the added value or revenue generated in a company through the processing of (purchased) intermediate products. By definition, the state grants energy-intensive companies a certain volume of emissions, for example through free certificates, but a CO2 levy is charged for emissions above this amount. This is intended to incentivise companies to make their production processes less energy-intensive.

The protagonists of the hydraulic refurbishment (from right): Brewery owner Alfred Oberlindober, plant engineer Lorenz Mayer, Sascha Unterrainer.

The waste heat flows into the 10 m high 85,000 litre storage tank. At the rear, the tank has six connections through which the waste heat suppliers feed in their different temperatures. The control system makes it possible to set the course, so to speak, depending on demand or quantity and, for example, to fill the connection for 40-degree water with 50-degree water if the situation requires it.

The majority of breweries use industrial gas, as 100,000 hectolitres or more per year can only be fermented with high electricity and fuel consumption. This is expensive. Even (still) without a CO2 levy, optimisation measures pay off. In the last seven years, the price of gas for industrial customers in Germany has doubled from 2.7 cents per 1 kWh to currently 5.44 cents (Schönram Brewery 2024/2025), having quadrupled by July 2022. The gas costs per 1 euro of turnover increased on average across all products from around 4.1 cents to 16.2 cents. In other words, natural gas accounted for around 16 per cent of the sales price (which was noticeable at the checkout in supermarkets). Although wholesale tariffs have normalised again to below 30 euros/MWh since the beginning of 2023, a company like the Private Landbrauerei Schönram brewery in Petting, Upper Bavaria, a stone's throw from the Austrian border, which produces 120,000 hectolitres of Schönramer Hell, Pils, Dunkel and Weiße every year, can only achieve this volume with 3.5 million kWh of energy purchases. Depending on the cost situation on the electricity and gas market, this adds up to 200,000 euros per year. A saving of 10 percent, for example through optimised hydraulics in the process chain alone, already saves 20,000 euros. And that every year. After ten years, there is already a "profit" of 200,000 euros, without any further intervention. Schönram's planner and plant engineer Lorenz Mayer, owner of the HVAC company of the same name in Petting, used figures like these to convince the management team led by owner Alfred Oberlindober and Sascha Unterrainer to modernise the fluid transport network for the process technology in 2015. Today, since August 2024, the proof has been on the energy bill. Although Sascha Unterrainer does not want to attribute the success of far more than 10 percent exclusively to the new hydraulics with the Rendemix multi-way mixing principle from Hückelhoven-based company Baunach, as certain outdated components, such as pumps with poor efficiency, were also replaced and further interventions were made in connection with the hydraulic overhaul, the optimised routing of the fluids is certainly the biggest contributor.

The natural gas-fuelled steam boilers each have a firing capacity of 1 MW.

Swirl tube heat exchanger (Spirax Sarco) for generating the maximum temperature in the buffer tank. The swirl tubes integrated in the tube bundle allow a high spread. The hottest temperature is supplied by the vapour from the condensate recovery system.

A flow 1 and a flow 2 run from the buffer cylinder through the entire operation. Flow 1 for temperatures up to 80 °C is not used regularly, however. Flow 2 provides the low temperature of approx. 50 to 55 °C.

Better than by hand

SHT had already presented the Rendemix process in previous issues, but the Pettinger Bierkocher's 10 years of experience with the Hückelhoven process encouraged them to take another look at the installation on site and possibly get confirmation that it doesn't always have to be extensive, costly renovation measures with a switch to renewable energies in order to reduce the burden on the environment. And that the hydraulic balancing required by the GEG and the KfW subsidy guidelines can be based on a finished product that both simplifies and outperforms any manual endeavours to adapt exact energy flows in terms of efficiency. Keyword exact: It is well known that efficiency leads to sufficiency, to partial renunciation. This is already of considerable benefit to climate protection. We should therefore start with this if, for whatever reason, the big solution cannot be realised. The origins of the Rendemix lie in the series connection of a high and a low temperature circuit. The underfloor heating on the ground floor, for example, uses the return flow from the radiators in the children's room and bedroom on the first floor as the flow, with the result that in principle only half as much heating water is heated and has to circulate. Due to the different volumes of water downstairs and upstairs in the house, the majority of system builders switched and still switch to two circuits, which, among other things, results in increased energy consumption. The developer of the patented process at the time, Hans-Georg Baunach, studied electrical engineering at the TH Aachen, so he knows a thing or two about currents. Sometime around the millennium, he converted volts and amperes into hydraulic sizes and units and moulded and screwed together his idea of more powerful hydraulics with control technology components to create an intelligent multi-port mixing valve.

Schönram is converting to modern compressed air generators (in the foreground). The devices deliver around 3 cubic metres per minute. The screw compressors supply the sterile air area, produce process air for automation, for switching valves and more.

The Baunach principle - in the picture the mixers without housing - is designed to achieve a stratification with a high delta T between cold and hot in the storage tank and to maintain the high temperatures for as long as possible by preferably using the amount of water from the centre of the buffer tank and injecting high-quality hot energy only drop by drop, so to speak.

Reheating is minimised

The single-circuit solution saves a considerable amount of energy. But that's not all. The multi-way mixer allows the contents of a buffer tank to be stably layered according to temperature, with a cold zone at the bottom, a warm zone in the centre and a hot zone at the top. If, for example, warm is sufficient to fulfil the desired requirement, the upper hot zone does not need to be accessed. If, on the other hand, the hot zone needs to be accessed, warm is added instead of cold. This means that the warm return flow from one consumer is always used to supply a second consumer with a cold return flow. This warm return flow from the first consumer no longer ends up in the centre of the buffer, but as a heated return flow from the second consumer at the bottom of the storage tank, so that the stratification is not affected. This remains stable and the stored valuable exergy is largely preserved. And thus a large delta T in the cylinder. The heat generator has to reheat much less frequently.

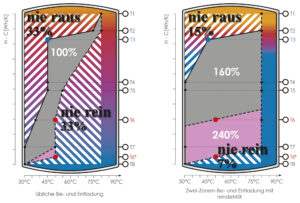

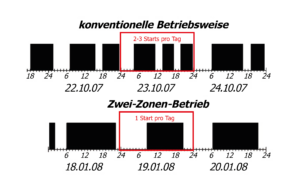

In an earlier presentation, Hans-Georg Baunach explained the advantage of maintaining a high spread using a simple example: "Imagine you have a well stratified storage tank with hot water at 80 °C at the top and cold water at 30 °C at the bottom. If you now mix it completely, you will have 55 °C everywhere. You have not lost any heat, but the stratification has been destroyed. The heat generator must start up. Not because the cylinder is empty, but because there is no more hot water. If the boiler has to start even though the cylinder is not empty, the buffer will not be able to fulfil one of its tasks of protecting the heat generator from too frequent starts and stops. With the usual consequences of high wear and increased start-up losses and thus useless waste of energy." The thinking behind the Rendemix, on the other hand, is as follows: It conserves the high grades. Without touching the loading temperature, this increases the capacity of a boiler in dynamic loading and unloading mode by up to 160 per cent, as Biberach University of Applied Sciences has determined in a test.

Long-term test at Biberach University of Applied Sciences: buffer charging and discharging according to the two-zone principle. The storage capacity increases by 160 per cent in two-zone operation and the boiler has to reheat much less frequently.

System efficiency instead of boiler efficiency

Main distributor with multi-way mixer

Lorenz Meyer realised the various advantages of the Baunach principle in Schönram. He read about it many years ago in SHT, studied it in more detail, trialled the technology and has sworn by it ever since. He practically no longer processes orders without this multi-way block. "I claim that if I equip two-family houses with Baunach stations and buffer storage tanks, this leads to energy savings of between 30 and more per cent. Of course, everything upstream and downstream of the Baunach station has to be right, right down to the integration of the pipes into the buffer cylinder, which is very often incorrect or inefficient. The cylinder is the most important link in a heating system. Boiler manufacturers promise you efficiencies of 92 and 93 per cent. This is of little use to me if the system is not optimised. I'm sure that many, even most heating systems achieve a maximum system efficiency of 75 per cent, and no more. This is partly because high temperatures are mixed in the storage tank and the energy generator has to constantly react and reheat." For some colleagues and for the end customer, the energy generator is the actual heating system. Which is not correct. Customers are led to believe that their investment has an efficiency of 92 and 93 per cent. "However, they lack any indicator for assessing efficiency. They accept the statement and don't know that their heat supply could be at least 20 per cent more economical. That's the reality." In many cases, it's all about selling, about making money. They are worried that they won't be awarded the contract because of the slightly more expensive Baunach mixer. "Colleagues are finding it difficult to market the effectiveness. The situation is this: When I explain the principle at a meeting or in a conversation, they are absolutely delighted. When they are then asked to install it, they are bothered by the extra cost. They're afraid of losing the contract and cancel the efficiency gain, forgoing the right technology between the energy generator, buffer storage and energy consumer. With the Rendemix principle, they would be in a completely different league when it comes to saving energy."

Cycle count comparison between two-zone operation and conventional operation

The beer flow

The malt obtained from barley or wheat (grain that has been germinated) is ground, crushed and placed in the mash tun together with water. It usually holds several thousand

litres. The master brewer heats this mash. During this process, enzymes convert the starch from the malt grains into malt sugar. The next step is to boil the mash and hops for a few hours in the usually dome-shaped wort kettle, also known as the brew kettle. This is where the hops, a climbing plant, release their bitter substances and give the beer its typical bitter flavour. The batch then goes into the fermentation room. At Landbrauerei Schrönam, fermentation takes place over ten days in open containers. The addition of yeast converts the sugar into alcohol and CO2. Finally, the Schönram brewery stores the raw beer in horizontal containers. Horizontal because certain desired reactions take place opposite it, which have to do with the special pressure conditions in the belly of horizontal storage tanks. Final fermentation in these tanks is followed by filtration to remove yeasts and sometimes harmful substances. After filtration, the beer remains for a relatively short time in the upright pressurised tanks (three in the picture) with an initial pressure of around 1.5 bar. From there it is filled into bottles or kegs.

Influence through wholesale

Pettinger is convinced that the wholesale trade also has an influence on this story. "They manage their specialist installers, provide them with the material, sometimes with plans and designs. Baunach is not on the track. The customer would have to say on their own initiative, stop, I don't want the material, I want the mixer station, I'll install it according to my own plan. But very few people go that far out on a limb." In the brewery, the Rendemix is connected to practically every heating circuit and every tank for low and high temperatures. The main storage tank for process water holds 85,000 litres. It stands ten metres high in one of the halls and collects energy from a wide variety of sources: from the heat generator, from the heat exchangers for heat recovery from the processes, from the return flow from heating circuits, process heat from steam generation, waste heat from compressed air generation. The condensation heat from the refrigeration systems for beer cooling also flows into the large container. "Our brewery endeavours not to waste a single kilowatt hour. We have installed a large number of heat exchangers for recovery. In the past, we used to blow some of it off through the roof. We no longer do that today. All the heat stays in the process," says Sascha Unterrainer. "There is also not a single hydraulic separator that mixes and devalues exergy with anergy. The consumer groups draw their requirements from the low pressure loss in the pipes. In addition, a small thermal buoyancy is created in the buffer cylinder by the hot and cool water. We utilise this buoyancy so that the water flows almost voluntarily to the consumer groups. We don't need a single flow pump."

Schönramer produces 120,000 hectolitres a year.

Low temperature where possible

The ammonia cooling system for beer and intermediate products has a waste heat output of between 80 and 220 kW and a flow temperature of between 33 and 39 °C. This makes it a low-temperature generator. This makes it a low-temperature generator, which is why many consumers in the building complex are designed for low temperatures. Hence the underfloor heating, extra-large radiators, radiant ceiling panels and concrete core activation. Of course, high temperatures are also required. For example, 65 °C for the 60 °C domestic hot water. The Baunach mixer is also responsible for this. The 85 °C stored in the buffer tank at the top of the dome comes from the boiler house. This supplies around 90 °C, the air compressors between 50 and 55 °C. Stefan Unterrainer, who is responsible for operations, emphasises once again: "The waste from our supply of around 3.5 million kWh, i.e. from heat recovery, is used to fully supply the heating water consumers in the building complex. Also the hot water preparation." 20 years ago, there were many oil-fired boilers in operation. By eliminating them, modernising the processes and heat supply years before the hydraulic optimisation and its own gas pipeline, the private brewery from 1780 regularly made it into the top 5 in an energy comparison at national level. This comparison relates to the efficiency of production. It wants to know how much energy is used to brew one hectolitre of beer. Heat by 50 kWh and electricity by 15 kWh for an output of 100,000 hectolitres. As Schönram is expanding, the company with its 120,000 hectolitres has now moved into the 100,000 to 500,000 hectolitre range. The company is still finding it difficult to achieve a top position. "Simply because competitors with 400,000 hectolitres, for example, can afford even more modern machinery," admits Sascha Unterrainer. Nevertheless, the company will do something about it and use heat pumps, among other things, next year. Of course, heat pumps, concrete core temperature control systems and underfloor heating systems must also be hydraulically balanced - and, for Lorenz Mayer, this is a matter of course, using the multi-port mixer principle.