Hydraulics made visible

Without alignment is like an orchestra without a conductor - A seminar in Arnsberg

Without alignment is like an orchestra without a conductor - A seminar in Arnsberg

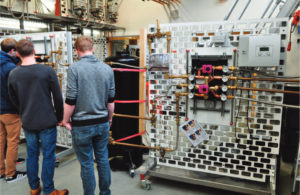

The need for information in the SHK-The training sector is huge. Yet further training does not have to be packaged in a lavishly designed social evening. If the topic is the standard problem area - hydraulics - and a non-sales-oriented institution invites, such as a chamber of crafts or the new energy communities, the training hall fills up. If an experiment in the heating laboratory then confirms the theory, at the end the listeners ask the host almost expectantly: "What's your next topic?"

Hydraulics as a problem zone. This is swelling more and more with networking digitalisation and the Internet of Things. In future, anyone who buys individual components for a sanitary, heating or air-conditioning system from a wholesaler will be buying puzzle pieces. As is well known, they only complement each other to form a complete picture if they are in the right place. In terms of hydraulics, the right place means the right adjustment. The individual components only work efficiently when they are optimally matched to each other. No one is able to build an efficient system with inefficient components. Combining efficient components into an inefficient system, on the other hand, is not the rule, but not the exception either. "Although every musician is a virtuoso, an orchestra concert without a conductor would not be a feast for the ears," was how the speaker at the hydraulics seminar in the vocational training centre of the Chamber of Crafts of South Westphalia in Arnsberg at the beginning of February placarded the need for professional balancing.

Loading and unloading of buffer storage tanks

Fig. 1: Test setup two-zone loading and unloading with multi-way mixer Chamber of Crafts Arnsberg

Buffer storage and its most efficient charging and discharging, for example, will have to take responsibility in the future not only for supplying buildings, but also for the energy transition. This is not an exaggeration. At present, heat storage also has the task of acting as an overpressure valve: because wind farms and solar farms are growing faster than the infrastructure. Than the expansion of roads. The experts calculate a transition period of a good ten years for the expansion. This means that in order for the grid not to glow, renewable energies would have to be taken off the grid in the next decade. That is not in the spirit of the energy transition. "That's why," said Stefan Kapferer, Chairman of the Executive Board of the German Association of Energy and Water Industries, recently, "we have to use every little measure that relieves the current situation. One of these possibilities is to use the surplus in households, namely to convert it into heat." The energy turnaround is one thing, making the infrastructure turnaround-ready is another. And this includes power-to-heat, among other things. The German energy and heating world is now becoming more electric with wind and PV power. The natural decoupling of supply and demand that goes hand in hand with this must be compensated for systemically. Convenient and efficient heating with energy that actually fluctuates is made possible by power-to-heat, i.e., among other things, sector coupling with a heat pump, with a thermal solar system and with buffer storage in order to store heat temporarily until the evening hours or into another time window. The more the control system utilises the capacity of such a storage tank, the more the overall system efficiency increases.

Incidentally, this applies to every integration of a buffer into a heating circuit, regardless of who supplies the heat: a condensing boiler, wood or pellets, the collector, CHP or the heat pump. But how do you approach the optimum? That was precisely the topic in Arnsberg.

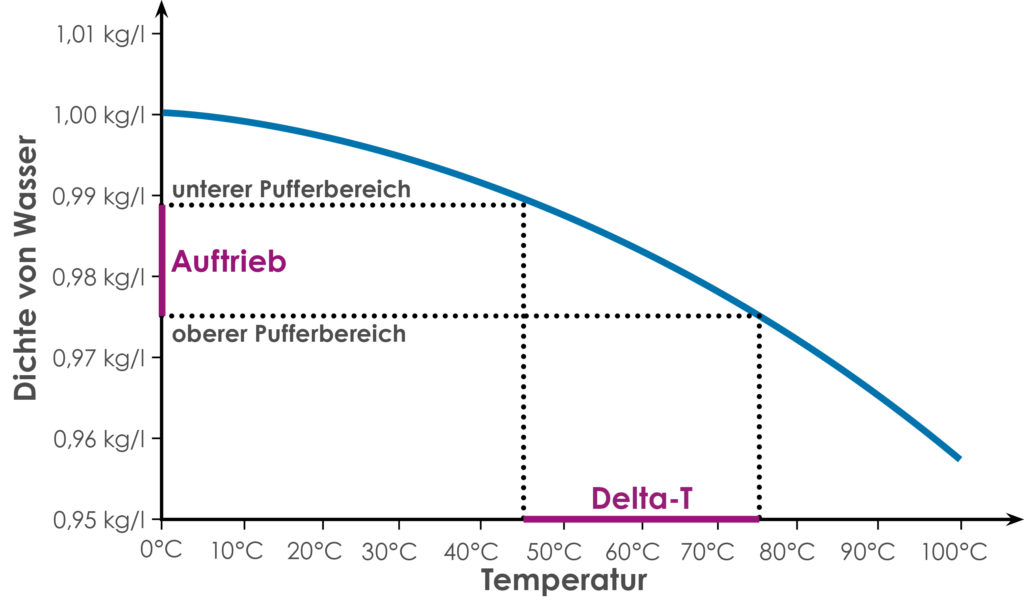

Figure 2: Buoyancy forces: The hotter the water, the lighter it is.

How do you approach the optimum?

Let's start with a question: How great are the buoyancy forces that stratify the warm and hot water? The excursion into hydraulics given by Hans-Georg Baunach from the company HG Baunach GmbH & Co. KG, came up with such little-known figures. Buoyancy is based on differences in density. Water at 0 °C weighs 1,000 g per 1 litre, water at 100 °C, right at the boiling point, only 950 g. The difference of 50 grams means that in a reservoir of 50 cm diameter - and thus with an area of around 2,000 cm² - a 1 cm thick layer of water with consequently the volume of two litres, roughly speaking, strives upwards with a compressive force of 100 grams - the buoyancy of boiling in ice-cold water. That is not much. Even the smallest disturbance to this low dynamic can take away the stratification will of the contents. Modest compensation: the lightness of the water increases disproportionately in the upper temperature range, so from about 50 °C onwards. In the cold range, on the other hand, between 0 °C and 20 °C, there is relatively little difference in density. In other words: the hotter the water, the more stable the stratification: and thus the usable heat content of a buffer or its usable storage capacity: Let's look at the loading. When the water is completely mixed to 50°C, the heat flows backwards, so to speak, counteracting the system idea. Namely, from the buffer into the 45 degree brine of the connected solar system, if the latter does not offer more than 45 °C. If, on the other hand, the content piles up from 30 to 70 °C, which means the same amount of heat as in the case before, the collector can deliver its solar gain to the cold zone of the water heater.

Destructive turbulence

Admittedly, all this is not unknown. But the majority of the listeners admitted that the consequences of incorrect charging and discharging of storage tanks are not considered so drastically. Or rather, they do not draw the conclusion from this: that above all the return temperature from a heating system should be as cold as possible. It is the decisive factor for the usable heat content. Firstly, it should be very low, secondly, the return flow should enter the buffer very far down and thirdly, it should flow at a low speed. So as not to create turbulence. Preferably at no more than ten centimetres per second. But this value is not a control variable. Because, of course, any turbulence destroys the stratification. We have already talked about the buoyancy forces. It, the turbulence, really builds up the misbehaviour of the tank, because the heat output of the flow depends on the throughput and the temperature. If the flow is to be 60 °C and only 70-grade storage water is available, more mixed water must circulate compared to an 80-grade fluid. A higher volume means a necessary increase in circulation speed. A higher circulation speed means an increase in the momentum of the water flowing into the tank - and thus an increase in turbulence. Baunach, the hydraulics expert, calculated the effect: The kinetic energy increases quadratically with the flow velocity, consequently the turbulence climbs by 77 per cent with a 33 per cent increase in throughput. This acts like a large whisk. It mixes all the heat zones into only a small delta T between top and bottom. The practical consequence: "If the mixed temperature in the boiler, let's say, doesn't go above 50 °C, the boiler will start after a few minutes when you take a shower, despite the solar system. With a 90/30 spread, on the other hand, the boiler stays off during showering and the collector can even still be loaded," explains Hans-Georg Baunach.

More efficient the more condensate

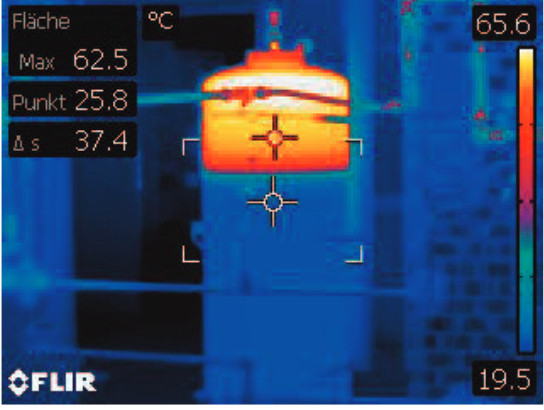

He has a corresponding slide ready for almost every statement. He does not expect that everything will be understood live right away. "At the beginning of many such training courses we register wide eyes, frown lines and astonishment. That's why we have a practical part. What sounds very complicated to one or the other, the laboratory experiment brightens up. It makes the theory understandable," Hans-Stefan Albers later summarised the feedback from the audience. Albers is head of the sanitary and heating engineering department at the South Westphalia Chamber of Crafts. Hydraulics seminars are part of his regular programme. The installations are dismantled in between to make way for other demonstrations, but are available again for the next course, refined. Refined means, for example, that the thermographic camera, which currently makes the stratification transparent, will soon be supplemented with a data logger with ten measuring points above the tank height. "Then we will be able to present precise temperatures to the participants," says Albers.

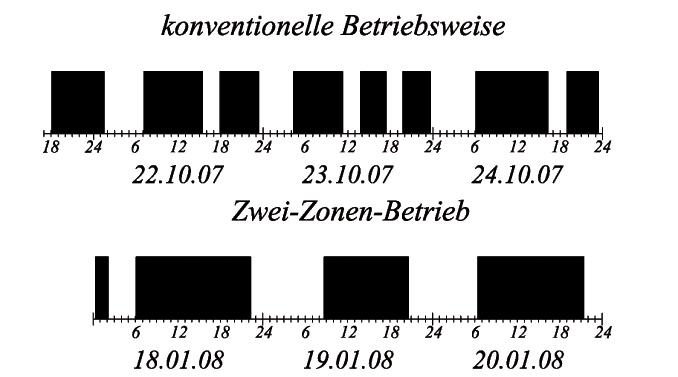

Gain of two-zone loading and unloading

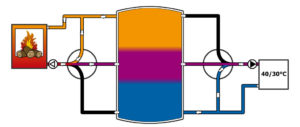

Fig. 1: Principle of two-zone loading and unloading with multi-way mixer

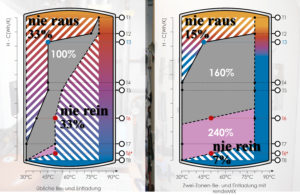

If the temperature of the violet layer is above the setpoint of this sensor, it tells the boiler 'Enough'. So the burner switches off. Consequently, only the stroke is available to the heating system in practice with the single-zone principle. The two diagrams for the single-zone principle on the left and the two-zone principle on the right show the temperature conditions during filling and consumption. The two dashed squares - with the water temperatures on the abscissa and the water column height in the tank on the ordinate - represent the theoretical storage capacity. The partial areas drawn in represent the real usable heat volume.

Figure 2: Results Biberach University of Applied Sciences

The explanation of their geometry and the individual measuring points T of the long-term test in Biberach is omitted here; the decisive factor is the different surface area: the charging and discharging strategies with the two multi-port mixers in the right-hand diagram are designed for a high spread in the cylinder. For example, in a design with radiator and underfloor heating, only the 30 °C return flow from the low-temperature heating system flows into the bottom of the tank, while the 50 °C radiator return flow is channelled into the mixing zone. The temperatures in the upper third remain similarly well stratified. The flow mixer may not even use the highest temperature, as the temperature of the centre zone is sufficient. The heat-led CHP unit therefore remains switched off. If the "Rendemix" draws heating water from the centre zone, it slims down and makes room for hot water from the "Dachs". In the standard case of the three-way mixer, on the other hand, the mixed return from the radiators and the panel heating already has a temperature of over 40 °C, depending on the output of the two heating circuits. Firstly, this is at the expense of the spread. Nothing can be taken directly from the violet hot zone. Secondly, this restricts the storage space for the hot water. And thirdly, the mixer has to draw on the valuable hot water supply for each flow temperature, which the machine then has to supply during the test.

Figure 3: Reduced start-stop cycles of the CHP unit with the same running time

The result: The usable storage volume for a two-zone loading and unloading with multi-way mixer in a system configuration like in the diploma thesis is exactly 2.4 times that of the single-zone design. Instead of the "roof" that was available in Biberach, there could also have been a boiler. With a boiler-storage combination, the conditions look exactly the same. By the way: The start-stop cycles of the "roof" were also reduced by a factor of 2.4.

It is very impressive "to see from the condensate quantity and to be able to calculate with it how low return temperatures increase the efficiency of a condensing boiler system and, in combination with a two-zone charging and discharging strategy instead of single-zone systems, the storage capacity of a hot water buffer," admits the head of department. His confidants at the vocational training centre are primarily master craftsmen. For practical proof of the efficiency of the special hydraulics according to the Baunach method - "It's almost enough to put your hands on the pipes. Then you can feel what's happening" - he had also invited the Energy Community of South Westphalia, which is a friend of the Chamber of Crafts. The company managers and owners, although in the middle of their professional lives and therefore largely familiar with hydraulics, were just as impressed by the results as the master students.

Figure 3: Thermographic image of the storage tank: beginning of stratification

Too cumbersome by hand

As I said, the Baunach development works through the three tasks of hydraulic optimisation, firstly system efficiency in heat utilisation, secondly system efficiency in heat distribution and thirdly system efficiency in heat storage, with a single fitting. Assembling this architecture manually from individual components requires a great deal of effort and expertise. With the "rendeMIX" it is sufficient to screw on the supply and return pipes. The origin of the mixer block was the idea of converting the prevailing costly and energy-wasting two-circuit systems, which send the high-temperature return from the radiators into the boiler instead of into the floor coils, into a fuel-saving single-circuit system. This requires balancing the different water volumes in the fitting. The company then extended the application to the optimal loading and unloading of two-zone buffer storage tanks and to the connection of solar systems. As part of a diploma thesis, the Biberach University of Applied Sciences determined the profit of an optimal connection with a buffer and a combined heat and power unit: Two-zone charging and discharging with one mixer each increases the usable heat content of a storage tank by 240% compared to the single-zone principle (see box). Naturally, the short laboratory test in Arnsberg could not come up with this astonishing value. Neither the equipment nor the time was sufficient. However, the measured temperatures and thermal performance tended to confirm the Biberach results.

Fig. 4: Condensate measurement (bottom centre) after return temperature reduction of the condensing boiler. Test manager Hans-Stefan Albers.