Product search

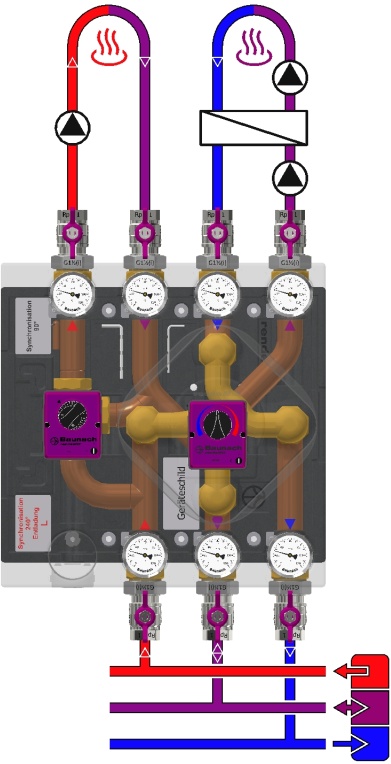

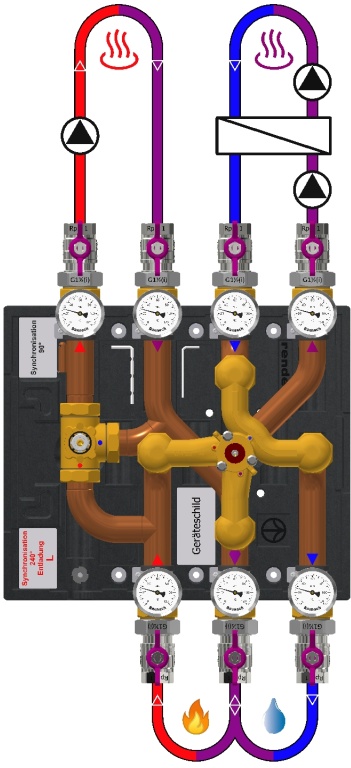

rSYS DN25 3x4+3mix R

Accessories needed

|

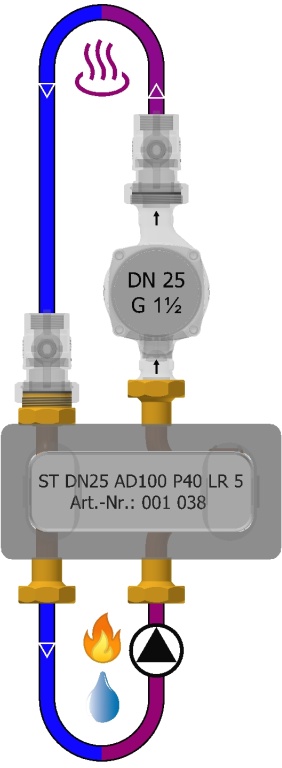

ST DN25 AD100 P40 LR 5001038 |

|

ST DN25 AD100 P40 LR001036 |

Further questions?

Contact technical supportConfigure product variant

Nominal width

Performance class

Kvs = 12.5 • V'max[100mbar] = 4m³/h

Q'max[20K] = 93kW

2nd mixing circuit (LT) for ST on-site:

Kvs = 9.4 • V'max[100mbar] = 3m³/h

Q'max[10K] = 35kW

Flow direction producer

Pump flange

Product documentation

Assembly instructions

Assembly instructions: For specialist partners only.

Please log in here or register here

Actuator multi-way mixer: For specialist partners only.

Please log in here or register here

Actuator three-way mixer: For specialist partners only.

Please log in here or register here

Spare parts drawing

Spare parts drawing For specialist partners only.

Please log in here or register here

Data sheet

GAEB

Tender text

Baunach article master data Version: 19.11.24

BAFA funding opportunity as part of heating system optimisation through hydraulic balancing and installation of separate control technology

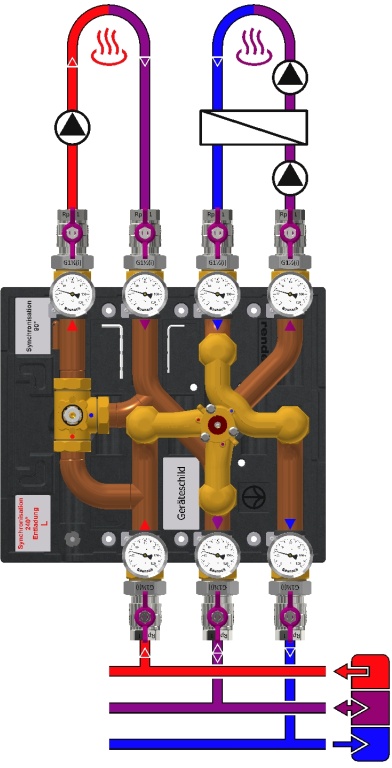

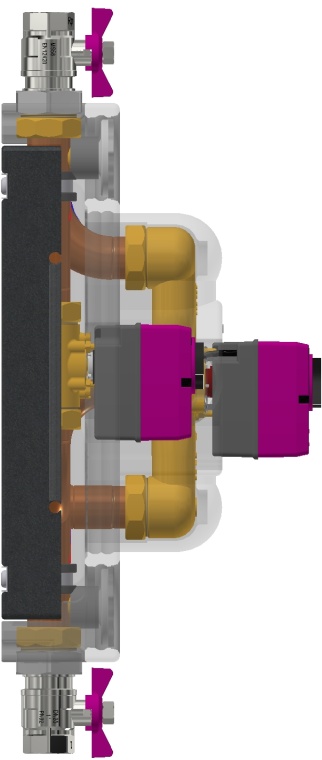

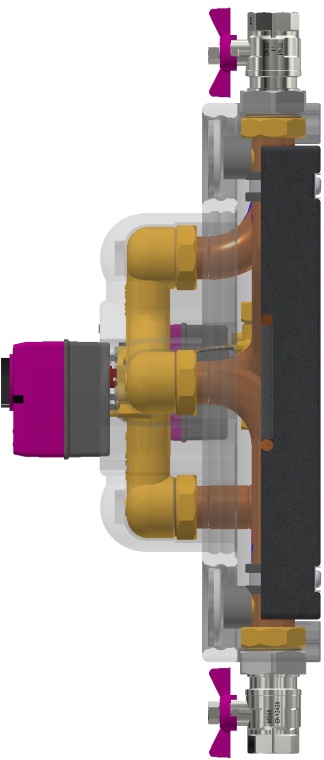

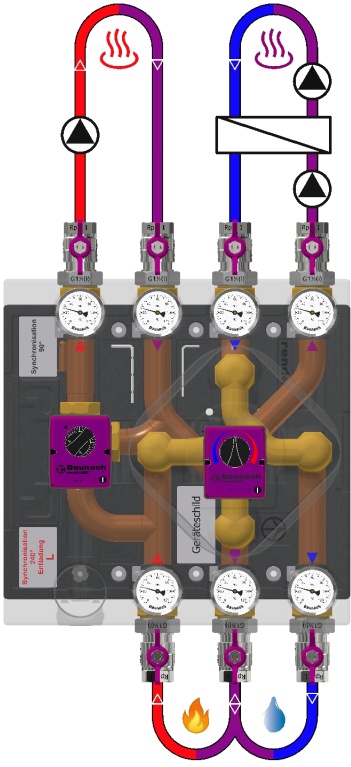

rendeMIX multi-port mixing manifold with 3/2-way tangential mixing valve DN25×G1½(a) MsGuss (red adapter) and 3-way mixing valve DN32×G1½(a) Ms58, plug and cover Ms58

For highly efficient two-zone unloading of a buffer tank in a mixed low-temperature circuit (2nd mixing circuit) by means of highly efficient operation of a system separation via flow control with highly efficient use of the return flow of a mixed high-temperature circuit (1st mixing circuit).

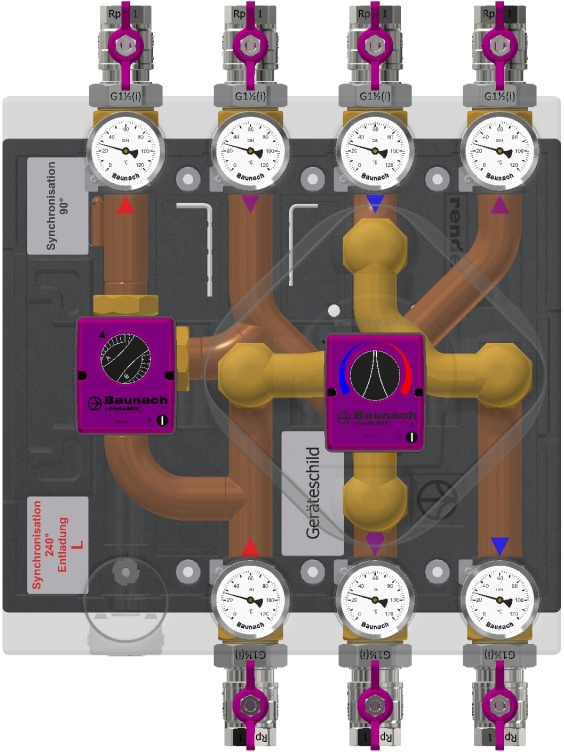

1st mixing circuit: EMS 90-3P actuator, 230V~ 50Hz 3.5VA 3-point signal, 5Nm (240h), 90°, 70s, grey adapter. 2nd mixing circuit: EMS 240 actuator, 230V~ 50Hz 3.5VA 3-point signal, 5Nm (240h), 240°, 93s

Two-circuit manifold assembly with 3 connections to the heat generator (buffer or boiler with flue gas heat exchanger), CuØ35×1, pipe spacing 100mm, DN32×G1½(a) flat

2 integrated gravity brakes/backflow preventer, Dp10mbar

1. mixing circuit (HT): Kvs = 12.5 - V'max[100mbar] = 4m³/h - Q'max[20K] = 93kW - leakage rate < 0.1% - 2nd mixing circuit (NT) for system separation on site: Kvs = 9.4 • V'max[100mbar] = 3m³/h • Q'max[10K] = 35kW • Leakage rate < 0,1%

7 Thermometer 0-120°C, Ø63mm, soldering sleeves Ms58

7 Ball valve screw connections, DN25, PN32, G1½(i)×Rp1 flat-sealing, stuffing box, sealing hole, spindle with aluminium wing handle

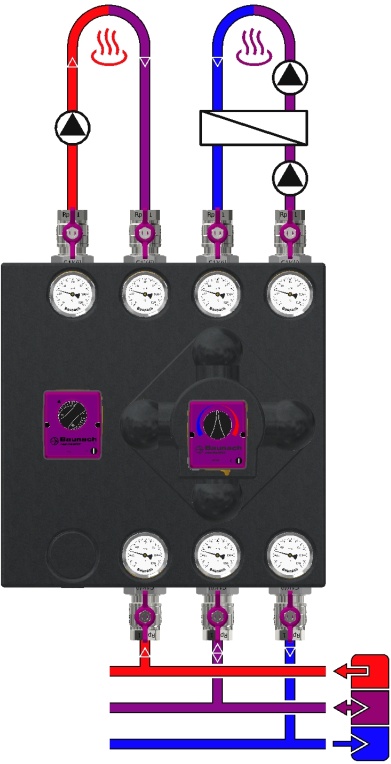

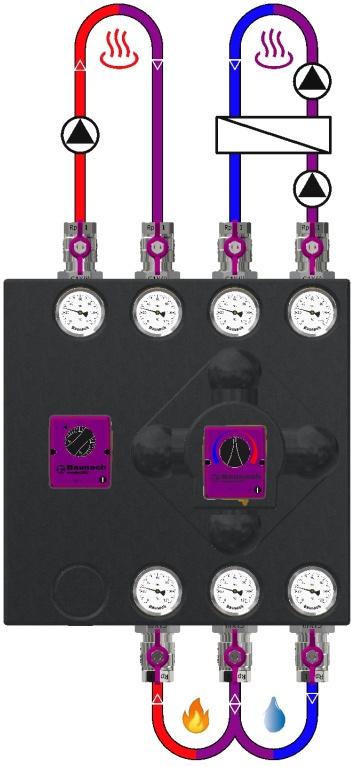

Insulating moulded tray EPP 40g/l, black, 450×450mm, quick assembly kit

Without pump flanges

Assembly does NOT include pump compensator - PAS L180 (Part No.: 001 338)

Assembly does not contain a pump

Model DN 25 - light version, PN 10bar, Tmax 120°C

ATTENTION: CANNOT BE USED WITHOUT SYSTEM SEPARATION!

Performance data

1. mixing circuit (HT): Kvs = 12.5 - V'max[100mbar] = 4m³/h - Q'max[20K] = 93kW - leakage rate < 0.1% - 2nd mixing circuit (NT) for system separation on site: Kvs = 9.4 • V'max[100mbar] = 3m³/h • Q'max[10K] = 35kW • Leakage rate < 0,1%