How David Kaiser with Baunach reduces system consumption between 30 and 50% on average:

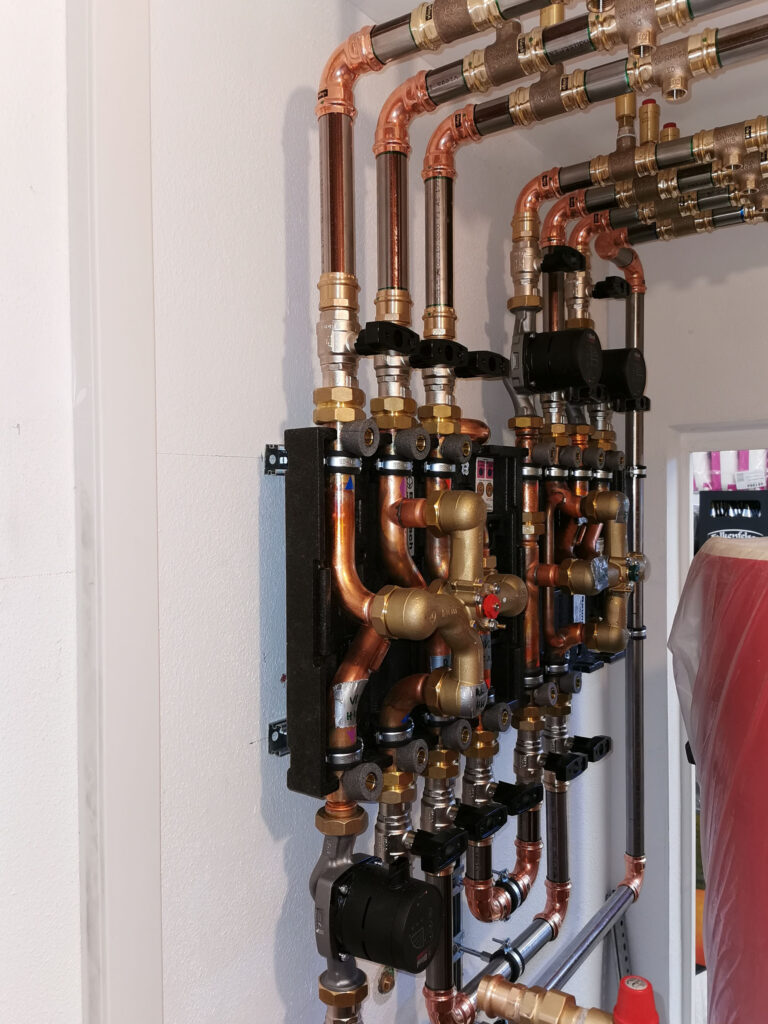

Journeyman Drin Tahiri (l.) and foreman Jörg Sautter (r.) installed the system.

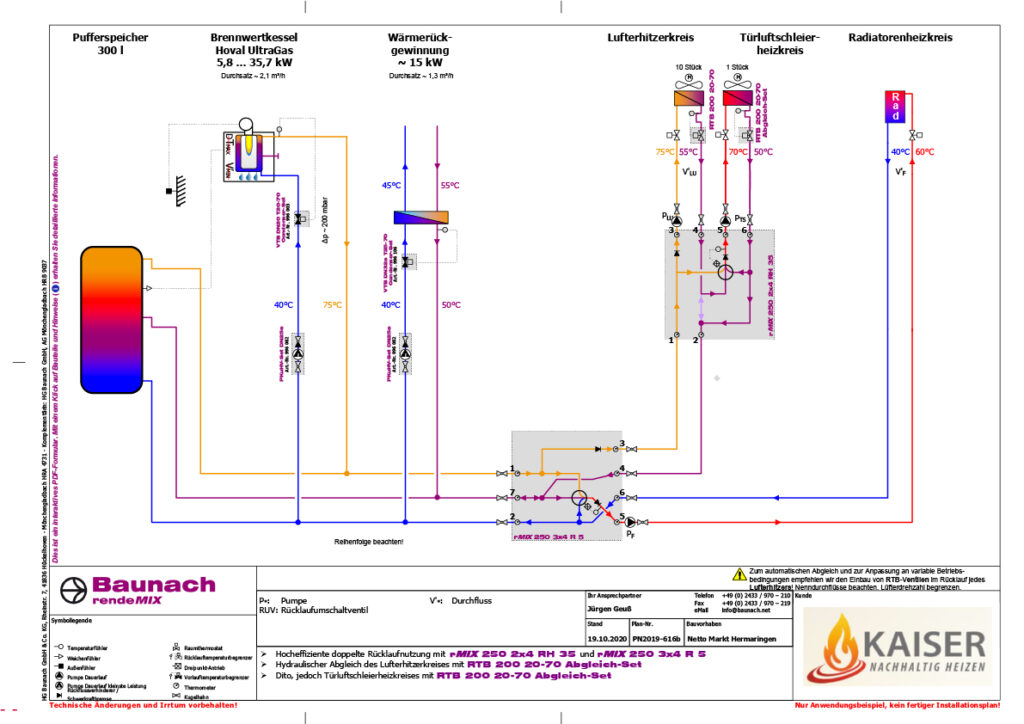

Baunach Fachpartner, Mr David Kaiser, Managing Director of the Kaiser Nachhaltig heizen GmbH from Gerstetten in Baden-Würtemberg, has the rendeMIX I first got to know it in 2018. Various facilities followed in the following years until today. In 2021, the Netto Markt (brand discount) facility in Hermaringen was implemented, which we would like to introduce to you in this article. David Kaiser uses a rMIX DN25 3×4 R 5 in combination with a rMIX DN25 2×4 RH 35. He is also an advocate of thermostatic balancing and has therefore equipped all air heater heating circuits with a RTB DN20 T20-70 adjustment set (nimble) equipped. Mr Kaiser regulates his heat generator using a VTB DN32s T40-100 Condensing set. Heat recovery is achieved via a VTB DN32s T25-70 Condenser Set realised. We asked Mr Kaiser about the plant and learned why he chose the rendeMIX and thermostatic balancing.

How did you become aware of the product?

Some time ago, I became aware of HG Baunach GmbH & Co. KG came to my attention. Already during the training I could see how efficiently and cost-effectively future projects can be realised.

Have you already gained experience with the efficiency of the plant?

Managing Director David Kaiser

Since 2018, we have been using mixers from HG Baunach GmbH & Co. KG have been in use. We have noticed that consumption has been reduced by between 30 and 50 % on average. The saved consumption is sustainable and accordingly very close to our hearts. Of course, this also benefits the customer.

Why did you decide on a Baunach product and what advantages do these products offer instead of a conventional three-way mixer?

The efficiency of your products is untouchable. Not many craftsmen dare to take the step of making their systems more efficient. Some lack the appropriate foresight. Products from HG Baunach GmbH & Co. KG are a unique selling point on the market.

Do you know other craftsmen or colleagues who use Baunach products?

I know two other people besides myself who use these mixers. There is definitely still work to be done to educate them!

Would you recommend that the Baunach system becomes part of the training at vocational schools, in master craftsman and technician training and in engineering training?

Yes, it should definitely be part of the training! Hydraulics should be taught much more. Above all, the advantages of hydraulics should already be taught in vocational school. This is how we achieve the most sustainable results in heating technology.

"The saved consumption is sustainable and accordingly very close to our hearts. Of course, this also benefits the customer."