Doubled capacity with the same volume

The trick with hydraulics - Hertweck optimises existing and new buildings

The trick with hydraulics - Hertweck optimises existing and new buildings

Niedernhall in the Hohenlohe region of Baden-Württemberg is "verRendemixt", there's no other way to put it. Word-of-mouth propaganda is to blame. It is known to beat even the most sophisticated marketing strategies. "VerRendemixt" means: the special multi-way mixer turns the return flow of a radiator heating system into the flow of a low-temperature underfloor heating system in numerous properties, thus saving energy. But not only that. In the numerous woodchip and pellet boilers in the region, it loads and unloads the buffer storage tanks provided with an efficiency that virtually doubles their capacity. Why?

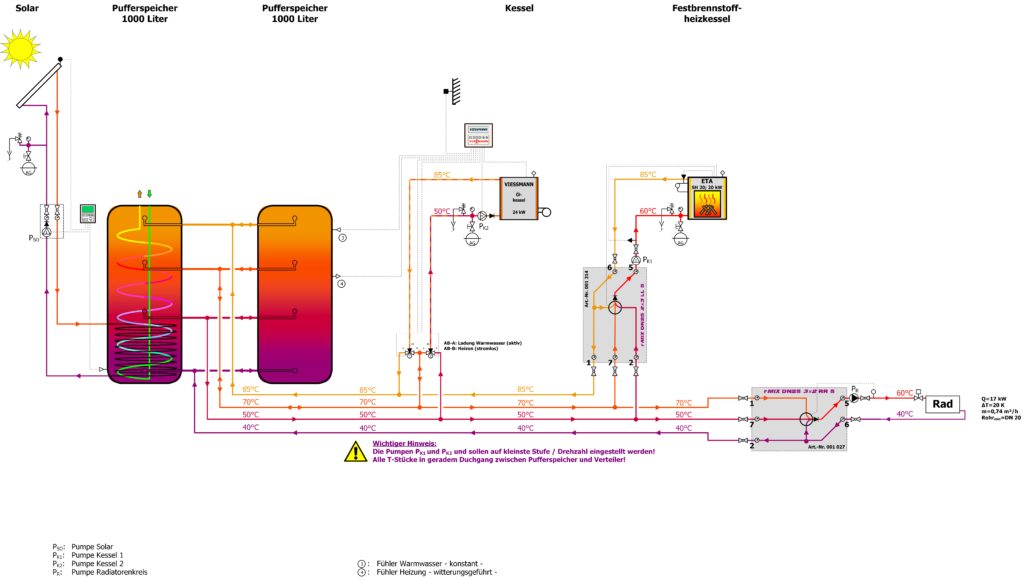

Fig. 1: Baumgartner building: Two multi-way mixers for energy-optimised loading and unloading of the two 1 000-l buffer tanks. Bottom left (blue) the solar heat exchanger on the buffer for hot water preparation. The red heating water buffer was already present. It is connected to the silver-grey stratified storage tank. The solar heat exchanger approaches the stratified tank in four different levels (temperature zones)

The Hertweck company is already in its third generation. Today it is run by Dipl.-Ing. Fritz-Jürgen Hertweck. He took over the business from his father, who is still a member of the management.

The company has 52 employees, 37 of whom work on the construction sites and 15 in the office. Hertweck handles about 70 per cent of the orders independently, i.e. it also does the planning, because the clients from the private sector mainly contact the plant constructor directly. Only in the commercial sector is the contract awarded via tenders and planning offices.

Renewable energy expert

The radius of activity in Hohenlohe is about 30 kilometres. The portfolio of the plant manufacturer includes all renewable energies up to local heating networks with biogas plants and woodchip boilers. In the region, building owners tend strongly towards pellets and all types of wood heating. In the urban areas of the region, demand for condensing boiler technology naturally dominates. But as soon as it gets outside the city gates, generative systems such as pellets, wood chips and log systems predominate, at least in Hertweck's order book. This trend applies to both new construction and renovation. Natural gas is also in the region, so that oil heating, which used to be predominant, is being pushed further and further back. Local heating also has its clientele. Here, Hertweck cooperates with a civil engineering company, although the pipeline construction is the responsibility of the SHK company.

For the single-family house clientele, the heat pump is of course also a possibility. Hertweck mainly installs air-heating systems because in Baden-Württemberg, after the accidents in Staufen and elsewhere, confidence in the geothermal option has been severely shaken. It is not the authorities that are putting the brakes on, but the fear of having to pay for the damage in the event of a disaster in the ground. The possible noise emissions from the outdoor unit of an air-source heat pump do not bother the neighbours here, because only a few terraced housing estates were built in the area around Niedernhall. The homeowners there have enough land area to set up the fan unit with sufficient distance to their own as well as to the neighbouring bedroom window.

Value creation remains in the region

Fig. 2: Niedernhall - biomass on the doorstep

Customers are also willing to switch from heating oil to pellets for renovation measures. Of course, this requires qualified advice. In the natural landscape of Hohenlohe, support is provided by the pronounced environmental awareness of the locals, as well as the visible biomass on the doorstep. With log and woodchip boilers, the added value remains in the region. On the fuel side, small and medium-sized enterprises in the area benefit from these furnaces, not the energy companies. In the case of pellets, the arc extends beyond the region, "but even here wood from German lands supplies the energy, not Russian gas or Arabian oil.

Finally, the price argument for the energy source also plays a role. It is probably 50 per cent cheaper than heating oil and 30 per cent cheaper than natural gas. The DEPV German Energy and Pellet Association regularly publishes the current comparative figures. Pellet prices have developed in a straight line with a gentle rise in recent years. Once, five or six years ago, there was an outlier, but it remained exactly that, the outlier. "Since then, there has been a stable and attractive difference to the other energy sources. Many builders also opt for a combination of wood or pellet heating plus thermal solar collectors. Photovoltaics, on the other hand, is finding fewer and fewer supporters because of the reduced remuneration."

Fig. 3: For log boilers and solar collectors (approx. 10 m2). Right rendeMIX 2 x 3 for loading (2 = flow and return boiler, 3 = buffer hot, warm, cold), next to it 3 x 2 for unloading (3 = buffer, 2 = consumer). The radio is set to discharge hot from the red buffer to the radiator heating (flow).

Hertweck carries out activities in the field of photovoltaics in cooperation with a specialised electrical company, especially when it comes to heat pump technology in combination with solar power feed-in. "This system technology requires a lot of know-how. We would have to install a separate department for it, which would exclusively take care of such combinations. That is not profitable. That's why we go down the path of cooperation with a qualified company. The client himself, however, has only one contractor, either us or our partner. We act as a joint venture. That must be a self-evident service with such offers."

"The live rendeMIX"

As mentioned in the foreword, the plant builder has literally "demixed" his surrounding area. He came into contact with the special hydraulic multi-way mixer from Baunach, Hückelhoven, through an article in a trade magazine. At the ISH trade fair in Nuremberg, Fritz-Jürgen Hertweck and his project manager Matthias Wied were encouraged to find out more about this energy-saving flow and return control from the developer Baunach. "What convinced us at this first meeting was not only the technology. The highly competent presentation of the processes in the mixer and in the network also showed us that not just anyone wants to sell something here. The Baunach people - this became very clear - stood and stand behind the product. They live and breathe rendeMIX.

So it had to be a good thing. "That's why we decided to work intensively with this technology and represent it to the client. We've managed to do that in over 50 projects with even more multi-way mixers - in some properties there are two or three hanging on the wall."

Wiring diagram rendeMIX

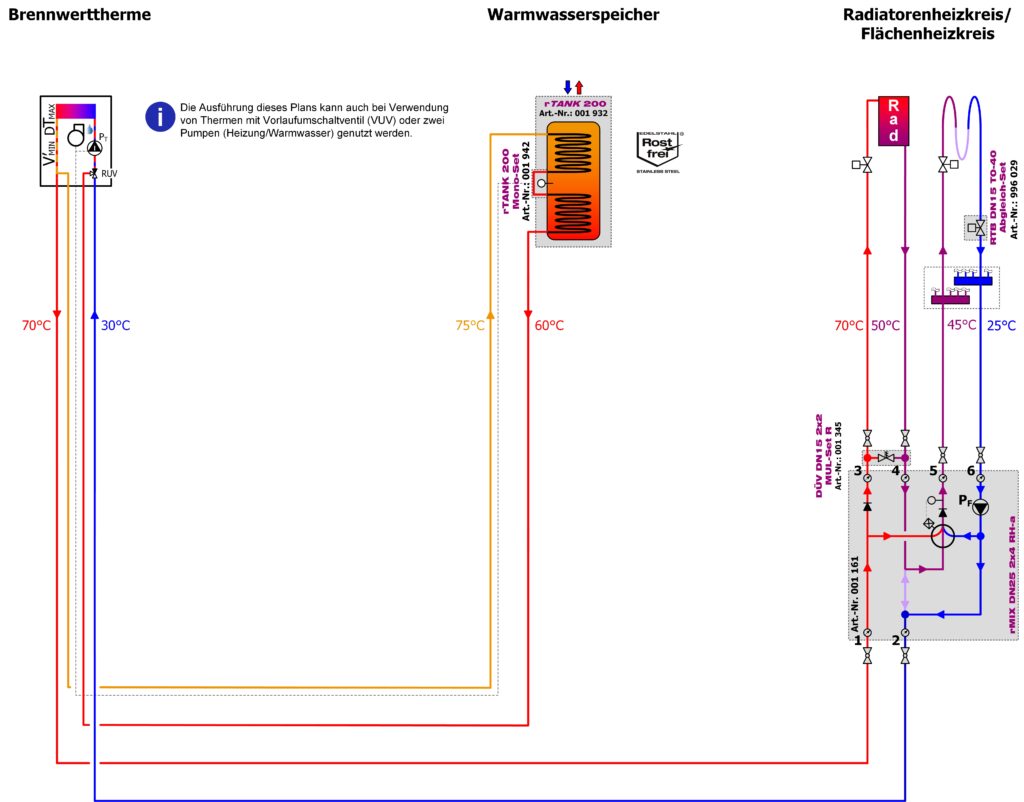

Fig. 1: Gas condensing boiler with an unmixed radiator heating circuit and a mixed underfloor heating circuit with a domestic hot water storage tank.

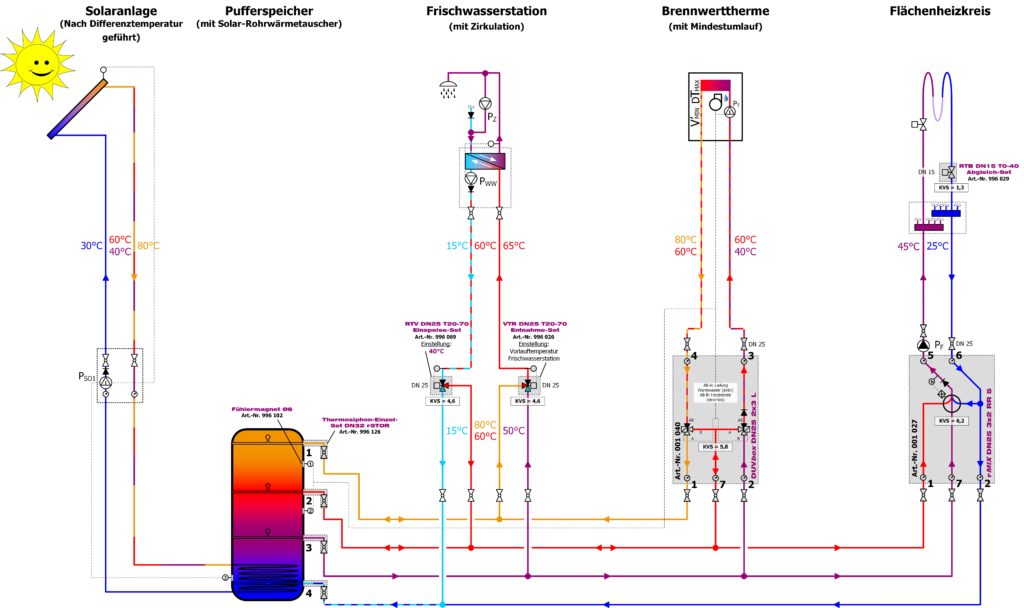

Fig. 2: Gas condensing boiler connected to a buffer cylinder with a mixed underfloor heating circuit and domestic hot water preparation via a fresh water module. Heating and domestic hot water preparation with solar support

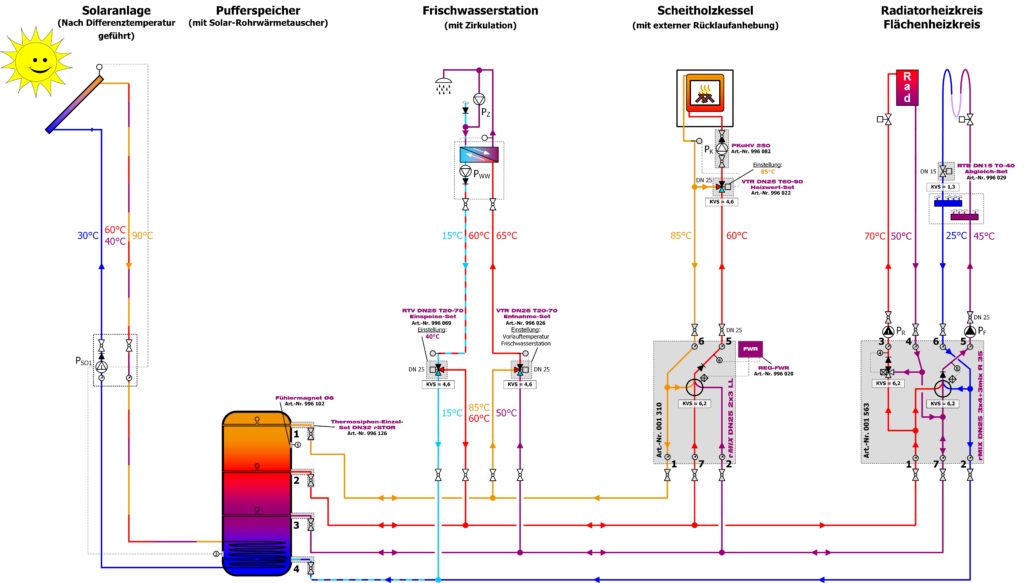

Fig. 3: Log boiler with two-zone charging in buffer storage via as well as two-zone discharging for a mixed underfloor heating circuit with return utilisation and a mixed radiator heating circuit as well as domestic hot water preparation via fresh water module. Heating and domestic hot water preparation with solar support

Fig. 4: Circuit diagram Baumgartner object

Three different applications

Fig. 4: Inlet cold water (drinking water coil), circulation line drinking water with mixer. Hot water temperature 40 °C

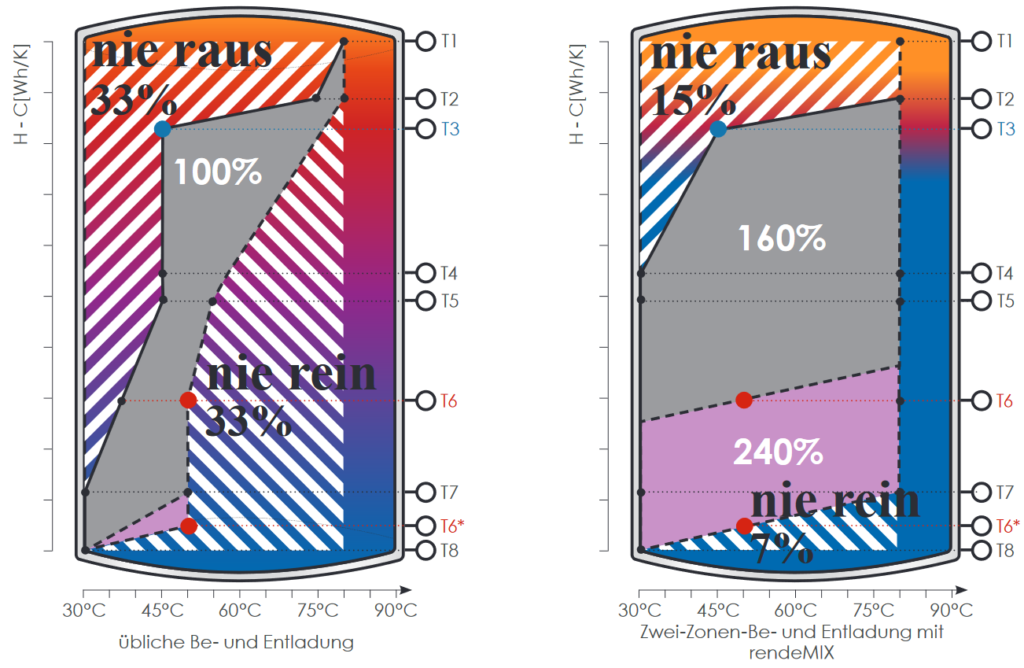

Hertweck uses the rendeMIX in a wide variety of systems. Firstly, classically for coupling the return of a high-temperature heating system (radiator) with a low-temperature heating system (underfloor heating). Here, the fitting almost classically turns the radiator return into the flow of the pipe coils in the floor. Secondly, for loading two-zone buffer storage tanks. In this case, the rendeMIX ensures that the stratification in the storage tank is maintained as long as possible by feeding into the corresponding zone depending on the source temperature. This type of loading prevents the mixing of the different levels and thus maintains the exergetic proportions in the storage tank as long as possible.

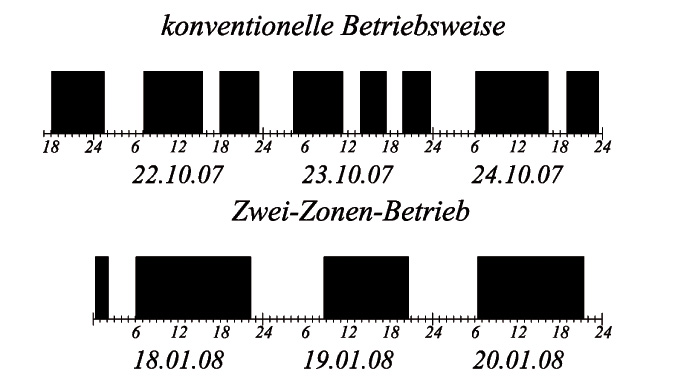

Thirdly, Baunach's control system discharges the hot water tanks in a similarly clever way. If a 40-gram temperature is sufficient, the multi-way mixer falls back to this level. It takes non-80-grade water and cools it down to 40-grade with a low return - which would result in considerable capacity losses. "Unregulated charging and discharging halves the capacity of a storage tank. This can be explained quite simply: if a flow of 50 °C is sufficient at noon and the multi-way mixer actually only takes these 50 °C, 80 °C are still available in the building in the evening from the upper zone. If, on the other hand, the control system had tapped the 80 °C and reduced it to 50 °C with cold water, the boiler would have to reheat in the evening. We promise the log boiler operator a considerable gain in comfort. The reheating interval is doubled. What used to be two days becomes four days. Our customers appreciate that.

Doubled capacity

Fig. 5: Hertweck installations. With rendeMIX, the payback time for the collector is halved

To add another example: "Imagine 3,000 litres of 40-gram water. At this temperature, you can't even take a bath or shower, if you include the gradient in the exchanger between the hot and buffer water. There are a few kilowatt hours in the water, but unfortunately not many valuable ones. Now divide the same energy content into 60-grd and 25-grd zones. The result: not only is there plenty of shower water available for the family, thanks to the two-zone loading you don't have to wait half a day until hot water is available again in the bathroom and kitchen, should you have used up the cushion at the top of the storage tank. The rendeMIX doesn't miss that. It reacts immediately by refilling this zone with high temperature."

The system builder elaborates on this point of comfort and energy gain using the example of solar feed: "Just take a look at single-zone charging. Water of any temperature always flows into the buffer via the same connection piece. As a result, water in the storage tank is stratified from 40 °C at the bottom to 60 °C at the top. What's more, it doesn't just flow in, let's put it that way, calmly. Turbulence is created in the boiler. This means that the cold and hot water components swirl together. If, on the other hand, a two-zone loading were carried out, there would be a relatively clean stratification with perhaps 30 or 35 °C at the bottom and 80 or 90 °C at the top.

This is a crucial downside of the single zone regulation.

Solar gain even in diffuse light

Fig. 6: Koch property. The builder: "It really is the case that I still have heat in the buffer on Sunday when I load on Friday. In the past, I had to ask children or neighbours to add wood in between."

The other: "Because of the 40 °C below, with an uncontrolled load, the solar collector cannot get rid of its low temperature. In diffuse weather, it could actually deposit the still perhaps 30 or 35 or 40 °C. But the heat exchanger does not react to this level: "On the floor where the solar heat exchanger is located, 40 °C is already present with unzoned loading. The pump only circulates the solar heat. If, on the other hand, the floor had 25 or 30 °C, the diffuse heat would also benefit the building owner." Spreading is everything. If it remains cold in the floor area of the buffer, the solar system can store more energy.

Fig.7: "The temperatures we measured for control purposes actually corresponded to the plan specification", Matthias Wied

Did the use of multi-way mixing technology require a long training period? Fritz-Jürgen Hertweck and Matthias Wied answer in the negative. "The unit does most of the work by itself. It is only controlled via the temperatures. We don't have to adjust any volume flows. The rendeMIX compensates for that on its own. Of course, you have to get to grips with your philosophy. For this, the company HG Baunach offers training material, the field service supports them or you go to a training course. But in principle, it's just as much about one or more pumps and a mixer as in conventional heating technology."

In the region, however, some conservative competitors observe Hertweck's technology and sales activities with suspicion. "Since they don't understand the system, they oppose it from case to case: 'You can spare yourself that, dear building owner, he only wants to sell you something. We sometimes hear this from our clients. But these colleagues overlook the fact that building owners today no longer trust their contractors unconditionally. They inform themselves in advance. They may not understand the details of a technique, but they quickly recognise the competence of their counterpart in the course of such conversations. With such remarks, they actually do more harm to themselves than to us. In any case, I don't know of any case where we have lost an order because of such 'clarification'," says the company boss.

Exam passed

Fig. 8: Temperatures and conditions on the display of the log boiler. Of course, it did not have to start on 6 August. The buffer was loaded by the solar collector.

Of course, the company did not trust Baunach's hydraulics naively during the start-up phase. "Everything that was presented to us sounded plausible, but trained marketing people always have the right arguments at hand. Every now and then, unfortunately, one is a burnt child. We wanted to know whether the temperatures and volume flows would really settle down as we were told. That's why we installed appropriate sensors and measuring devices in the first installations - and were not surprised, but very satisfied when the values actually behaved according to plan. Only this proof made us rendeMIX supporters."

The sympathisation started about ten years ago. At that time, the coupling of the radiator circuit with the underfloor heating was predominant. More and more, however, the company discovered the advantages of optimal charging and discharging of storage tanks, especially in combination with the pellet and wood boilers that are widespread on the doorstep. "In fact, our customers have confirmed time and again that they can go into the weekend with peace of mind since the conversion, because it is enough to let the boiler burn for four or five hours on Friday to fill up the storage tank(s) and thus be sure that there is enough usable - the emphasis is on usable - energy in the buffer until Sunday evening as well as being called up. On Sunday evening, she returns regularly to a cosy warm home."

Previously, in the days of the old wood-fired heating system, the operators had to add fuel in the morning, at noon and in the evening. When the first wood gasification boilers with buffer storage came along, this necessity was reduced to once or twice a day at the most. The modern wood or pellet boilers, which have become even more efficient, in combination with a stratified storage tank of 2,000 or 3,000 litres, allow for a refuelling "of perhaps every two days, unless it is Siberian cold outside. With the 'rendeMIX' as the highest level of hydraulic optimisation, we can easily extend this range by twice as much. As a rule, it is sufficient to light the logs only on Mondays and Fridays," Fritz-Jürgen Wied emphasises the enormous gain in comfort.

Stock can be converted to two-zone buffer

Fig. 9: Just as innovative heating technology is a matter of course for the Hertweck company, the presentation of contemporary bathroom fittings is just as natural for the plant manufacturer.

In principle, any buffer can be converted into a stratified storage tank. "During refurbishment, we often come across a boiler that is still in working order. For example, we then just replace the old wood boiler with a contemporary pellet boiler, replace the standard return temperature increase with a multi-way mixer and also convert the adjacent 1,000-litre tank to two-zone charging with a rendeMIX. It's part of our standard work to weld in the necessary nozzles in individual cases, should they not be available." Compared to a new boiler, this is not quite as effective, since the modern designs with their internal water baffles favour stratification, "but you also have to look at the customer's money. At some point, the customer says in the course of a consultation, that's enough. You have to be able to afford to save energy. But I'm only talking about the last five per cent.

But the farm owner does have one wish. What is missing is "a rendeMIX one size smaller. The currently rather bulky fitting covers a wide range of flows, but the multi-way mixer offered does not have to provide 30 kW for the smaller family home. After all, overdimensioning is expensive. In addition, the current size restricts us in terms of installation. Many houses without basements make do with a relatively narrow chamber as a boiler room. To accommodate the distributor on the wall there often requires a few pull-ups.

Fig. 10: rendeMIX more than doubles the buffer capacity.

Fig. 11: With the larger buffer capacity, both the reheating intervals ...

Fig. 12: ... as well as the usable solar yield, whose fuel savings halve the payback period.

Bernd Genath

www.hertweck.biz

www.baunach.net