Parallel or one behind the other?

What to do with several buffer storage tanks?

Systems are increasingly being equipped with buffer storage tanks, whether for heat pumps, wood boilers, CHP units or solar systems. It is not uncommon for the necessary storage volume to have to be divided among several smaller tanks because only these fit through the doors or stairwells. This raises the question of whether a parallel or back-to-back connection of buffer storage tanks is the better solution. As usually in life, the appropriate answer is: "It all depends."

Systems are increasingly being equipped with buffer storage tanks, whether for heat pumps, wood boilers, CHP units or solar systems. It is not uncommon for the necessary storage volume to have to be divided among several smaller tanks because only these fit through the doors or stairwells. This raises the question of whether a parallel or back-to-back connection of buffer storage tanks is the better solution. As usually in life, the appropriate answer is: "It all depends."

Basically, our customers, readers and interested parties know that the efficiency of heat storage depends to a large extent on the stratification in the storage tank. And for stratification, a slim and tall storage tank is certainly better than a small and wide one with a large diameter.

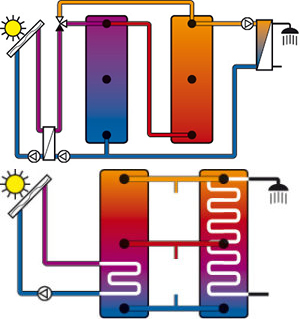

Image 1

Figure 1 shows a buffer tank with three connections in parallel. It is quite obvious that with the parallel connection the total volume is distributed over several tanks via the cross-section. It can also be seen that the number of tanks can be increased as desired. The important thing with the parallel connection is that

- all containers are at the same height

- all connection ports (1) to (3) belonging to each other are at the same height

- the connecting lines run exactly horizontally

- the connecting lines are as short as possible, have no bends and large cross-sections

- the connection lines always open vertically into the connection lines

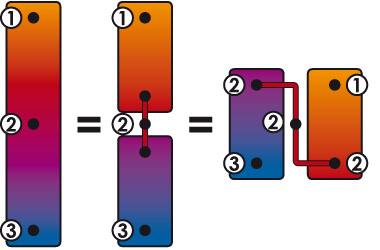

Picture 2

Figure 2 shows the parallel connection of buffers with four connections, for which the same conditions apply. Again, it is important to note that one can choose the number of containers independently of the number of connections, which is a great advantage of the parallel connection.

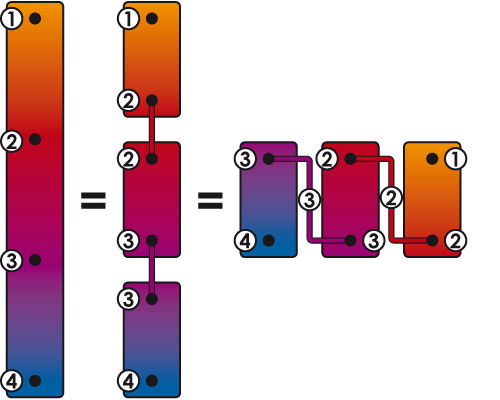

Image 3

Figure 3, on the other hand, shows the series connection of two buffer tanks. It is clearly visible that in this case the total volume is distributed over the height of several tanks. While in the parallel connection all tanks contain the same temperatures, in the series connection there are tanks with different temperatures. Also, the number of tanks in series corresponds to the number of storage zones, which is directly related to the number of connections. In Figure 4, for example, three tanks are connected in series, which corresponds to a buffer with four connections (1) to (4). For stratification in the buffer, connecting them one behind the other is certainly advantageous. Also, the containers do not have to be at the same height and the connecting lines do not have to be horizontal, straight or of particularly large cross-section. So all in all, only advantages?

Picture 4

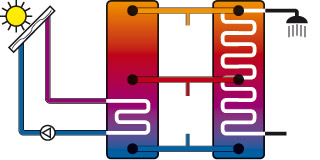

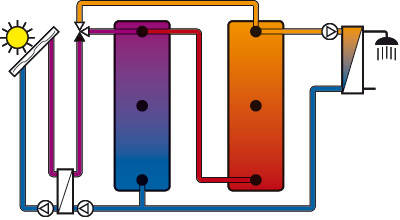

Picture 5

No, because there is also a serious disadvantage of the series connection: No gravity compensation is possible between the individual containers (buffer zones)! Fig. 5 explains what this means: If, for example, a buffer with an internal solar heat exchanger and one with an internal DHW coil are to be combined, this can only be achieved via gravity compensation and thus parallel connection. With a series connection, the solar heat would never reach the DHW in summer. If, on the other hand, a solar loading station and a fresh water station are used, as shown in Fig. 6, a series connection can be used, as the stations ensure the heat transport between the individual tanks with their pumps. However, it must be ensured that the loading station also loads the upper or hotter buffer in summer, i.e. that it contains a stratified charging module (differential temperature switchover valve). If this is ensured, the series connection can fully exploit its advantages over the parallel connection.

Picture 6

Discover our products for this purpose:

Thermosiphon Series Set DN32 rSTOR

For connecting two buffers in series and connecting to a

Single pipe with thermosiphon

Thermosiphon single set DN32 rSTOR

For connecting a buffer to a single pipe with thermosiphon

rSTOR 1000 P2

1,000 litre steel buffer tank with two fixed discs

to reduce the turbulence caused by the flow

rSTOR 1000 P3

1,000 litre steel buffer tank with three fixed discs

to reduce the turbulence caused by the flow

rSTOR 1000 P4

1,000 litre steel buffer tank with four fixed discs

to reduce the turbulence caused by the flow