A problem solved

Hydraulic balancing: The trick with return temperature limitation

Hydraulic balancing: The trick with return temperature limitation

Repeatedly demanded but rarely carried out professionally: Although hydraulic balancing is probably the most effective low-investment energy efficiency measure, it is usually only carried out half-heartedly, especially in the renovation of old buildings, because of the various unknowns. A completely new method, which impresses with both its simplicity and its effectiveness, has now passed its field tests for underfloor heating. Among others, in the house of a church energy consultant in Lower Franconia.

Whether the Christian imperative of "safeguarding creation" was the deciding factor for his commitment to energy-efficient building technology came to light during the pastor's visit to SHT. Christof Bärhausen in the Franconian town of Maibach. About 30 years ago, the World Council of Churches wrote the imperative into the programmes of the political parties, so to speak, and thus apostrophised ethics as a powerful foundation stone of sustainable environmental policy. Talking to the South German theologian, however, it seems to have been more physics than metaphysics that drove him not only to preach efficiency but to competently demonstrate it to his congregation: He simply has a strong inclination towards technology. A penchant that is not content with the level of a gifted layman. Christof Bärhausen went deeper into the subject. He finally received the high consecration from the Chamber of Crafts for Lower Franconia, before which he took the "exam with all the trimmings" (Bärhausen) to become an energy consultant (HWK). Seen in this light, physics and metaphysics intertwine in his work: today, the churchman makes his practical contribution to the preservation of creation in his own home and through "house-technical" community work.

Figure 1: A total of nine heating circuits supply the house, five on the ground floor, four for the upper floors. Each heating circuit has its own return temperature limiter (on the lower return manifold). RTB fittings will also be installed in the risers to the left of the radiators on the top floor. Furthermore, it is intended to connect the radiators, which are now oversized due to the energy refurbishment of the attic, as low-temperature heat exchangers directly to the flow and return of the floor circuit. The dynamically controlling RTBs hydraulically balance the installation. The three actuators on the right react to the impulses of the electric room thermostats.

Guided by mistrust

First, a look into the past: the unsatisfactory integration of the solar system via buffer into the oil boiler system of his residential building at the time confronted him for the first time with the laws of hydraulics and with the realisation that it, the hydraulics, must be the very first starting point for optimisation measures. How should temperature stratification, charging and discharging be structured in order to give away as little solar gain as possible?

The Roman Catholic pastoral minister studied the flow paths in the multi-way mixer "rendeMIX", which came onto the market at the time, about 15 years ago, and which had been brought to his attention by an engineer friend. He installed it. The Baunach development with its internal bypasses balances different water volumes and thus allows, for example, the return of a high-temperature circuit (radiator) to become the flow of an underfloor heating system. Or it first takes unmixed water from a two-zone or multi-zone boiler - thus retaining valuable high-temperature exergy - before mixing hot with cold. As it strives to stabilise the spread in a stratified storage tank, it also increases the solar yield because the tank itself still takes collector heat a few degrees above cold due to its cold zone.

On the current problem

The success of the mixer retrofit at the time was demonstrated by the heat meter at the Bärhausen plant. It ran more slowly. The positive experiences confirmed to the energy consultant the importance of correct and sensitive hydraulics. At the same time, however, they made him suspicious about the savings effects of further measures that had been tackled, such as a curtain-type wooden façade with 21 cm of insulation between the boarding and the stone, roof renovation, insulating glazing, and the reduction of thermal bridges, which were supposed to raise the single-family house from the time before the first heat insulation ordinance to the KfW 55 standard. How do you regulate the water flows in an old building with a large number of circuits for living rooms, bedrooms, children's rooms and offices, for kitchens and bathrooms, for rooms under the roof with now oversized radiators, for underfloor heating in the living area to the lowered demand?

Photo 2: Typical of southern German architecture: underfloor heating below, radiator heating on the upper floors.

Fig. 3: Return temperature setting on the RTBs between approx. 17 and 22 °C, depending on the room and heat exchanger size, use and desired temperature. The fine adjustment is up to the user.

With older thermostatic valves without the possibility of presetting the flow? But even those with presetting would react relatively statically "open" and "closed" and not efficiently dynamically, in terms of water volume, to regulate changing influences and conditions. The KfW subsidy regulations prescribe hydraulic balancing - and, as described, for Christof Bärhausen it was a must anyway.

Dynamic instead of static

As chance would have it, Hans-Georg Baunach, the fittings designer and managing director of HG Baunach GmbH & Co. KG from Hückelhoven near Aachen, had been thinking along similar lines for some time. His tests and successes with the "rendeMIX" had taught him that hydraulic balancing carried out manually remains a mixture of trial and error - if a trial at all. The classic method also has to live with the weakness that the calibration to a fixed flow rate gives away some of the gain potential. Baunach's multi-way fitting "rendeMIX", however, does not serve this purpose. Its purpose is to mix water of different temperatures, not to regulate water flows. The engineer therefore looked for another solution to the regulation problem. It had to be both optimal and simple.

"Simple" in two respects: the trade must accept it and the price, let's put it this way, must increase its acceptance. The calculation should not be made with the saved working time compared to the effort for the usual adjustment. Hardly any company would make such a calculation. It was only allowed to be a one-paar-euro product. The idea of return temperature limitation as thermal-hydraulic balancing was successful. For about a year now, various pilot projects have been running, including the Bärhausen plant. It is nothing more than a return temperature limiter, as the name suggests: an RTB valve for installation in the return of a heating circuit behind the heat exchanger.

Figure 4: The potential thermal bridges at windows and balcony doors are minimised with an insulating fill in such a way that they do not jeopardise KfW 55.

Figure 5: The heated living space totals 160 m2, of which 120 m2 Underfloor heating and radiators in the attic. Next to the windows, the ventilation valves of the decentralised ventilation units. Christof Bärhausen in the picture.

The design variable is solely the nominal size of the return. The fitting works thermally-dynamically. In other words, it constantly adjusts the flow to the setpoint at the adjustable return temperature sensor: if the temperature rises, it reduces the flow through the heating coils in the floor; if it falls, it ensures a higher circulation flow. It thus takes over the hydraulic balancing of the circuits or the flow control through the low-temperature radiator or the floor coils completely independently and oriented to the room temperature. Room temperature-oriented: This may still be set with the thermostatic valve on the radiator or with an alternative individual room control, only now the flow volume is harmonised with the room air setpoint via the return temperature. Without any physical connection, both fittings correspond with each other.

Figure 6: The house is heated by an (older) vegetable oil CHP unit, which was supposed to feed into a local heating network, but which was not realised. A wood stove with a water pocket is also connected to the unpressurised combi buffer tank (1,000 l), which could also heat all the rooms. The overpressure in the storage tank must not exceed 0.1 bar. Therefore, it is hydraulically decoupled from the heating system via a heat exchanger (far left). The lower "rendeMIX" is responsible for the two-zone loading of the combi buffer cylinder with integrated heat exchangers. The stratification guarantees sufficient hot water for the kitchen and bathroom. The upper multi-way mixer served to efficiently integrate the solar thermal system in cooperation with the peak load boiler at the time.

Ideal because without any calculation

How does it work? For the basic setting, room-related empirical values must also be used on the RTB, as is usual with thermostatic valves. An example: The bedroom should be 18 °C. The thermostatic valve is set to level 3. The thermostatic valve is presumed to be set to level 3. On the flow side, level 5 or 23 °C on the scale of the thermostatic valve may be sufficient for these 18 °C. The setting on the thermostatic valve must also be based on the thermal properties of the room. As I said, the setting depends on the thermal properties of the building. Towards evening, the outdoor and room temperatures drop. The radiator valve opens. Without RTB, the full nominal flow rate would rush through the heating surface almost spontaneously, affecting other circuits. The RTB, on the other hand, waits.

Technical data valves

Currently on sale are the return temperature limiters for underfloor heating circuits (RTB-Fbh) as well as a version for the thermal-hydraulic balancing of heat exchangers on domestic hot water storage tanks, air heaters, swimming pool heat exchangers and room air conditioning systems (RTB balancing set). Fittings exclusively for radiator heating systems are currently being tested. The underfloor heating variant, as in the Bärhausen property, consists of a brass lower part and the thermostatic head with integrated temperature sensor. As is usual with thermostatic valves, the setpoint value of the return, which is coordinated with the room air temperature, is adjusted with the twistable cap on the upper part. The RTB supports and accelerates the self-regulating effect of the floor heating. Its return temperature increases when the room temperature rises, i.e. the excess temperature of the heating surface compared to the room temperature decreases. The usual two-point single room controller, which can only switch the circuit on and off, blocks the flow in this case. When the controller opens, it directs the full water flow through the circuit, i.e. it does not intervene in the volume flow. Therefore, all underfloor heating circuits have to be calculated in a not uncomplicated way and then the calculated water quantities have to be adjusted via a control element. This is a very time-consuming method. And of course all the settings influence each other: once the last three loops have been fitted, the current that should flow through the first circuit is guaranteed to have changed. The method resembles an equation with many unknowns. The optimal point is a matter of chance.

Currently on sale are the return temperature limiters for underfloor heating circuits (RTB-Fbh) as well as a version for the thermal-hydraulic balancing of heat exchangers on domestic hot water storage tanks, air heaters, swimming pool heat exchangers and room air conditioning systems (RTB balancing set). Fittings exclusively for radiator heating systems are currently being tested. The underfloor heating variant, as in the Bärhausen property, consists of a brass lower part and the thermostatic head with integrated temperature sensor. As is usual with thermostatic valves, the setpoint value of the return, which is coordinated with the room air temperature, is adjusted with the twistable cap on the upper part. The RTB supports and accelerates the self-regulating effect of the floor heating. Its return temperature increases when the room temperature rises, i.e. the excess temperature of the heating surface compared to the room temperature decreases. The usual two-point single room controller, which can only switch the circuit on and off, blocks the flow in this case. When the controller opens, it directs the full water flow through the circuit, i.e. it does not intervene in the volume flow. Therefore, all underfloor heating circuits have to be calculated in a not uncomplicated way and then the calculated water quantities have to be adjusted via a control element. This is a very time-consuming method. And of course all the settings influence each other: once the last three loops have been fitted, the current that should flow through the first circuit is guaranteed to have changed. The method resembles an equation with many unknowns. The optimal point is a matter of chance.

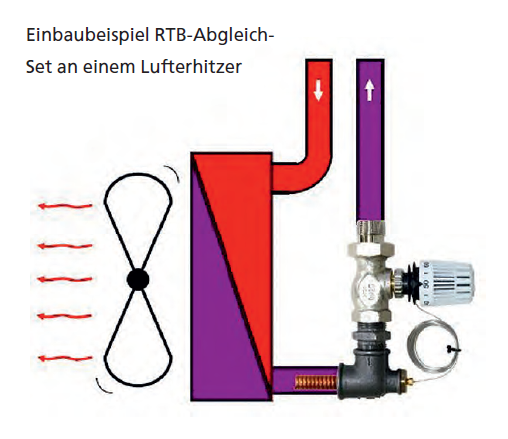

With the return temperature limitation in the form of a proportional RTB valve, on the other hand, exactly the power that the partial area is supposed to deliver always circulates through the partial areas. The return temperature as a controlled variable dynamically regulates the flow. For practical application, Baunach recommends installing the RTBs directly on the return collector of the manifold. Nominal size of the valve DN 15, pressure loss 100 mbar at a flow rate of 0.40 m3/h, Kvs value 1.3 m3/h, adjustment range return setpoint 0 to 40 °C, permissible operating overpressure 10 bar. The second model, the RTB balancing set for automatic thermal-hydraulic balancing of the flow rates of heat exchangers of drinking water storage tanks, air heaters, swimming pool heat exchangers and air-conditioning systems, is available in three sizes: DN 20, 25, 32, Kvs 2.5, 5.7 and 6.7, output at 20 K Delta T 18, 42 and 49 kW. Return temperature range 20 to 70 °C.

In contrast to the RTB-Fbh, a remote sensor with capillary tube is attached to the thermostat head for arbitrary placement of the sensor in the return of a heat exchanger. Both variants, the one for underfloor heating as well as the one for various heat exchangers and air heaters, operate exclusively thermally-hydraulically without external energy. They do not close completely. A minimum flow of 1 % of the nominal value is guaranteed so that the sensor is always immersed in return water.

It opens slightly when the return temperature tends to drop due to the falling outdoor temperature, and it slims down the throughput when the room thermostat has opened completely, i.e. the measured value at the RTB sensor now wants to climb above the setpoint. This does not deprive the other heating circuits of heating water. Of course, their RTBs also react by opening the cross-sections. The entire system automatically adjusts itself. Nothing changes in the principle of output control of the highly efficient, self-regulating circulating pumps. They automatically adjust their wattage to the differential pressure. Christof Bärhausen enthuses: "Before, we couldn't get a grip on it. In the upper rooms, the room thermostats alternated between being fully open or fully closed, and the large heating surfaces sucked the water away from the others or overloaded them. We could never get all the rooms evenly warm, despite attempts at hydraulic balancing.

With RTB, the amount of water remains limited. We have done the fine adjustment ourselves. The upper part of the valve only needs to be adjusted slightly and only once to a setting that provides the desired room temperature. You certainly have to touch it. But you have to do that with every thermostatic valve."

Audible success

For the other planned renovation measures on and in the house, the energy consultant therefore does not use presettable radiator valves, "because they only let a constant amount through. They don't work dynamically. For the presetting, I would have to carry out a heating load calculation for each room. I save myself that with the RTB. Now quite classic radiator thermostats are enough." The owner is sure that the thermal-hydraulic balancing alone will result in a noticeable reduction in the vegetable oil bill for his CHP unit. Originally, it was supposed to supply some of the neighbours in the local heating network. However, they later backed out, but for certain reasons the oil boiler was replaced by the power-heat coupler. It already clocked up noticeably less in the first phase of the energetic afforestation, in that half year when initially only the RTBs were installed. "At least something had changed audibly.

Figure 7: Return temperature limiter test in a chemical factory in Limburg, Belgium, with an RTB behind each of the 30 fans supplied with hot water. The thermocouple prevents the return temperature from climbing above 45 °C due to low heat removal of the heat exchanger by adjusting the delivery rate of the circulating pump due to the increased differential pressure. The return water thus becomes suitable for condensing.

I can't come up with a degree day correction, but the situation looks like this: according to general experience, better heat distribution saves 10 to 15 % of heating energy on a statistical average. This will also be true for us, as the CHP started up much less frequently immediately after the RTBs were adjusted. Incidentally, we have noticed this effect a second time. We also noticed this at the time of the oil boiler, after installing the "rendeMIX" fitting in the solar circuit. The volume of the combi buffer cylinder was better utilised, it gave off heat for much longer and the boiler recharged less frequently."

Fine-tuning by the residents

The electoral Franconian has rolled up his sleeves. He has work to do. The pipes in the boiler room need to be insulated. "What you see here is really not a modern heating system in that sense. Everything is put together and fiddled with, and yet everything works wonderfully." At the distributor on the 1st floor, he explains the settings: "We now see the four rooms here: the big room, south room and bathroom, the north room. The last one never got to the room temperature we wanted.

The electric actuators here in the manifold cabinet are linked to the room thermostats in the three rooms. The bathroom should always be a little warmer, so it is completely open from the flow. Thanks to the setting options on the RTBs, we can finally get the room temperatures down to the exact degree. As we used to use the large room as a bedroom, the heating pipes in the floor are relatively far apart. That's why I adjusted the return to 20 degrees. For the other two rooms, 15 or 16 degrees is enough and I set the return temperature in the bathroom to 22 to 23 degrees. The flow temperature for all rooms is 30 °C. By raising the average temperature between the flow and return in the bathroom to 26 °C, I keep it at around 24 °C. A similar consideration with regard to the average temperature also applies to the "large room".

Just a little patience

Mr Bärhausen, in your experience, what do you have to tell a planner or system builder with regard to return temperature limitation? "Nothing really. As I said, the system adjusts itself. There is no presetting in this form. You have to approach it with some sensitivity and look at the room, its use, its north/south position, its heat exchangers/radiators and pre-adjust to a value.

Figure 8: Two decentralised individual room ventilation systems with ceramic heat recovery units are installed per room. They act alternately as supply and extract air units, switching from extract air to supply air operation every 70 seconds. For the Vento-Expert type, manufacturer Blauberg states a flow rate of up to 50 m3/h and a heat recovery efficiency of 97 %. www.blaubergventilatoren.de

Every user or homeowner can then readjust it himself. Be a little more careful with underfloor heating. It is a sluggish system, so it takes a little longer. If you adjust the RTB by maybe two degrees, you should be patient for a day or two and only then look at the effect. But you don't need a calculation. As far as I know, it is the only system that works like that. With all other methods for hydraulic balancing, I have to take into account the radiator size and other factors and bring them into interaction in order to adjust the presettable valves or zone valves accordingly. And then they are almost set. Whether it works is not guaranteed. Here, the operator makes the readjustment, but sets it to a temperature setpoint, not to a cross-section and thus to a flow rate setpoint. The RTB looks for that itself."

Sample confirmation for KfW

KfW has agreed with the VDZ, the leading association of building technology, on a procedure for hydraulic balancing that must be documented in a corresponding form. However, KfW does not oppose innovations. It states that it is possible to deviate from the established procedure if the alternative can be assigned to point 5.25 "Opening clause for innovative technologies" of the leaflet responsible for heating efficiency measures (KfW publication 600 000 3140). For heating contractors whose customers wish to claim KfW/Bafa funding and who request confirmation of hydraulic balancing, Baunach has prepared a corresponding sample.

Bernd Genath